In the world of material handling, furniture design, and equipment mobility, casters play an essential role in improving functionality and flexibility. Among the various types available, side mount casters have gained popularity for their unique mounting style and versatile applications.

What Are Side Mount Casters?

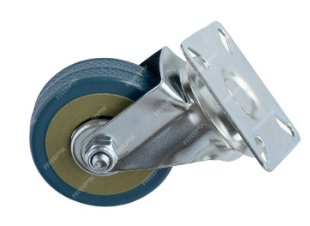

Side mount casters are wheels designed to be attached to the side of a structure rather than the bottom. Unlike traditional bottom-mounted casters, side-mounted models are fixed using brackets or mounting plates that attach to the side frame of the item — making them ideal for narrow bases or items with limited bottom surface area.

Key Benefits of Side Mount Casters

1. Space Efficiency

Because they are attached to the side, these casters allow for more clearance beneath the equipment or furniture. This is particularly useful in compact environments or when a lower profile is required.

2. Enhanced Stability

Side-mounted designs can distribute weight more evenly, especially in tall or narrow units. This can reduce tipping risk and improve balance during movement.

3. Easy Installation

Most side mount casters come with pre-drilled holes or universal mounting plates, making installation straightforward and time-efficient.

4. Versatile Applications

From medical carts and workshop benches to server racks and mobile storage units, side mount casters are suited for both industrial and commercial use.

Common Types of Side Mount Casters

Swivel Casters — Allow 360° rotation for greater maneuverability.

Rigid (Fixed) Casters — Offer straight-line movement for heavier loads.

Locking Casters — Include brakes or locks to keep equipment stationary.

Heavy-Duty Casters — Built to handle substantial weight without compromising mobility.

Materials and Load Capacities

Side mount casters are available in various materials such as polyurethane, rubber, nylon, and metal. The choice depends on the application:

Rubber casters are quiet and ideal for smooth surfaces.

Polyurethane provides a balance of durability and floor protection.

Steel or cast iron casters are better suited for heavy-duty industrial applications.

Load capacities typically range from 75 to 1,000 lbs per caster, depending on construction and wheel material.

Choosing the Right Side Mount Caster

When selecting side mount casters, consider the following:

Weight requirements

Surface type (indoor/outdoor, smooth/rough)

Mobility needs (fixed vs. swivel)

Mounting compatibility

Environmental factors (temperature, moisture, chemicals)

Final Thoughts

Side mount casters are an efficient, practical solution for adding mobility without compromising stability or space. Whether you’re retrofitting existing equipment or designing a new product line, these casters offer flexibility, strength, and ease of use in one simple component.

Write a comment ...